As AI technology and smart driving are booming, the demand for data processing speed and capacity is growing explosively, and the demand for efficient data transmission has brought many challenges to the connector industry. Recently, Amphenol , TE, Molex and other leading connector manufacturers have launched a number of high-performance connector products that can meet the connection needs of AI, data centers, autonomous driving, industrial automation and other fields.

Molex

CX2 Connectors and CX2 Dual Speed Connectors and Cable Assemblies

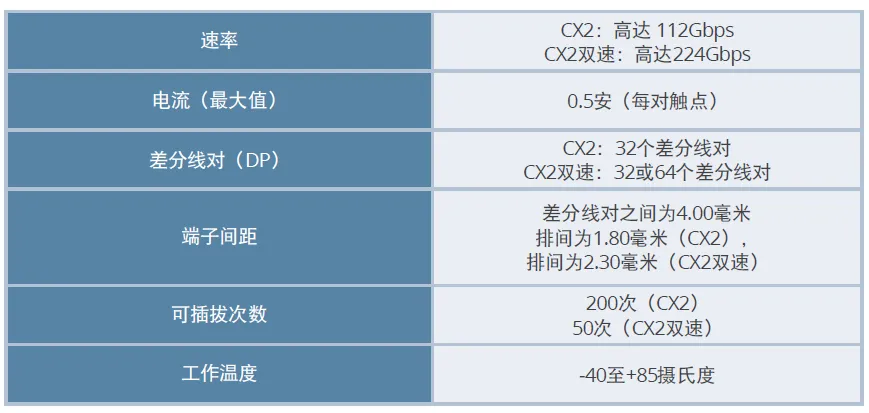

CX2 connectors and CX2-DS connectors and cable assemblies help customers meet AI-driven demands for higher speeds and greater capacity, providing near-chip cable connector solutions. They support next-generation data rates and enable chip-to-chip direct connection system architectures. These systems support the transmission of high-speed signals from near the chip to other parts of the system via twin-axial cables, significantly improving signal integrity (SI) and system performance compared to using PCB traces.

Supports next-generation data rates up to 112G (CX2) or 224G (CX2-DS)

The pin layout of the isolated transceiver/receiver uses an innovative shielding structure and is equipped with a high-performance twinaxial cable, which helps achieve a transmission rate of up to 112Gbps on the CX2 connector. The CX2-DS is an enhanced version of the CX2 with doubled/enhanced signal rate and bandwidth. The CX2-DS connector can achieve a transmission rate of up to 224Gbps.

Improves reliability and ensures that connectors are fully seated to prevent mismating and accidental disconnection

The two-piece mating kit consisting of the connector and receptacle features a mechanical wipe and can be secured with a latch or screw.

Maximize system performance and extend connectivity within the box

Cable assemblies use 31 AWG (CX2) or 30 AWG (CX2-DS) twinaxial cable to support BiPass

Cable system architecture solutions.

Minimizes the risk of damage to PCB connector pins during installation

The fully protected, anti-mating interface simplifies assembly and helps ensure that the connectors mate securely.

Ability to reduce crosstalk and improve signal integrity, enabling higher signal rates. This design ensures high-speed performance while minimizing signal degradation.

Amphenol

Paladin®

ExaMAX® Backplane Connectors

XCede® High-Density Backplane Connectors

AirMAX®

TE

Paladin®

- Backward compatibility, Z-PACK HM-eZD++ receptacles can be mated with existing Z-PACK HM-ZD headers for field data rate upgrades

- Available in a variety of data rate options: Z-PACK HM-ZD (12.5 Gbps), HM-ZD+ (15 Gbps), HM-eZD+ (2025 Gbps) and HM-eZD++ (56 Gbps) (PAM4) and 32 Gbps (NRZ)

- Suitable for Advanced Telecom Computing Architecture (ATCA) with various traditional and coplanar options

- Global design and engineering support enables TE to provide a wide range of products for customers to choose from

- Z-PACK HM-eZD++ connector supports 56 Gbps data transfer rate, density up to 30DP/inch, and improved electrical performance

- Headers and sockets of different data rate versions are compatible with each other

- eZD++ connectors feature smaller plated through-hole sizes (minimum 0.31mm for signal pins and 0.36mm for ground pins), providing greater design flexibility and better high-frequency performance

- Pre-alignment and polarization features are integrated into the rugged mating design, and a solid ground shield increases mechanical durability

- High durability, up to 200 mating cycles (maximum), resistant to 50G mechanical shock

- Operating temperature: -55°C to 105°C

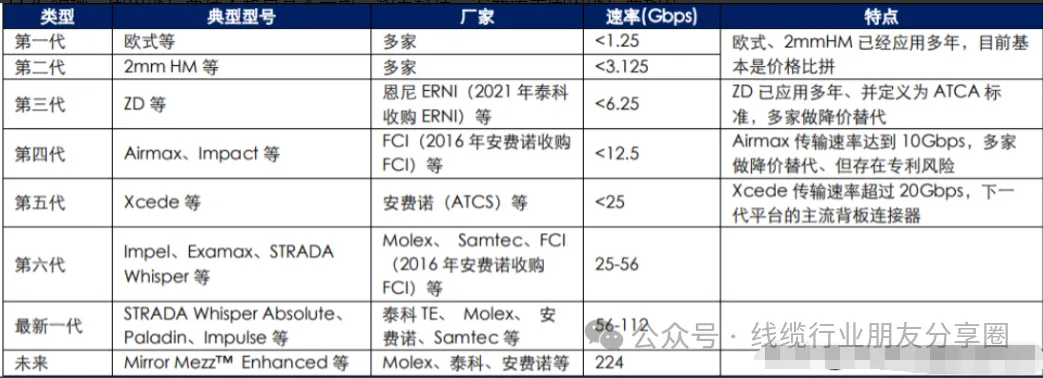

As users’ requirements for transmission speeds become higher and higher, high-speed backplane connector suppliers continue to optimize their products. The adjustments mainly include the use of flexible interference connection circuit board technology, which allows the holes of the circuit board to be made smaller, and the use of customized plastics to compensate for signal delays, or the recommendation of expanding the holes in the circuit board. The development of semiconductor technology enables high-speed connector manufacturers to showcase their higher-frequency products. The high-speed connector market has experienced an era of explosive growth in new interfaces, and these new interface high-speed backplane connectors are fully prepared to meet the competition of the new generation of applications. At present, the global backplane communication connector market is mainly dominated by overseas leading companies, and the main manufacturers include SAMTEC, Amphenol, Molex, TE, etc. The above four companies have a total of nearly 600 invention patents related to high-speed backplane connectors. Due to the high technical difficulty of high-speed backplane connectors, overseas companies have made relevant layouts earlier. According to the “Research Report on Key Electronic Components (Abbreviated Version)” of China International Engineering Consulting Co., Ltd., in the field of high-speed connectors of 25Gbps and above, the three major American giants, Tyco, Amphenol, and Molex, have acquired and mutually authorized patents . The above four companies have a total of nearly 600 invention patents related to high-speed backplane connectors. Due to the long-term monopoly, a market pattern of “one dominant company and three strong companies following” has been formed. Domestic manufacturers are currently starting to buy authorized OEMs from these companies to produce some low-end products themselves. The ones that are doing better at present are Huafeng, Qinghong, AVIC Optoelectronics, Luxshare , Yihua, Dingtong, and Xiangfang Electronics . With the rapid development of the IT industry, the diversity of transmission quality, speed, and application levels has triggered a continuous driving force for the development of faster transmission speeds. In order to increase the signal transmission speed, all individual components must be able to minimize signal attenuation, distortion, and anti-interference. Therefore, high-speed connectors as transmission “bridges” also need to be upgraded, because they play an increasingly important role in transmission quality and speed. In the 224Gbps rate era, in order to pursue higher port density, connector companies will evolve towards QSFP-DD connectors that support 800G port capacity in the future. At present, QSFP-DD connectors are only used on relatively high-end servers, and internal storage connectors are mainly Mini-SAS and Mini-SAS HD, which will use more high-speed backplane connectors such as Gen Z, Slim SAS, and MCIO. With the growing demand for applications, China’s AI server shipments continue to grow. With the accelerated development of downstream industries, high-speed backplane connectors, as an important component of AI servers, continue to expand their market space. It is expected that in the future, with the rapid development of high-tech industries such as cloud computing, artificial intelligence, autonomous driving 5G/6G, and the metaverse, the market size of high-speed backplane connectors for AI servers in China will continue to grow, and it is expected to exceed 10 billion yuan by 2029. At present, it is known that many listed companies in the cable industry have invested in this track. The rapid increase in computing power demand has driven the demand for AI servers. The transmission rate of backplane connectors has been upgraded to 112G and 224G, driving the rapid increase in the value of high-speed backplane connectors. There is a huge room for replacement by leading domestic manufacturers.